A copper elongation alloy, production is

The handling alloy

Alloy number | Characteristic | Use |

(65:35 brass) | Cold-work-related rolling characteristics are good and turn for complicated processing product, deep drawing processing by processing as the strength is high, and a bending spirit, the shallow diaphragm nature is good. | Electric appliance material, household articles, communication machine, precision instrument parts |

(brass for the bending) | In muntsumetaru, I turn to the cold room between the heat for bending together. | Wiring appliance, nameplate, apparatus parts, |

(one kind of excellent cut brass) | With moderate ductility, I am used for a high-speed automatic lathe and, also, am suitable for processing between the heat. | Bend valve, parts of the machine |

(two kinds of excellent cut brass) | It is the brass that cutting characteristics were largely improved by adding lead.

I am used for a super-high-speed automatic machine, and the tool life gets longer than one kind. | Parts, gear, valves such as the precision instrument or clock |

(brass for forging) | I am used for a forging and pressure mark between the heat. | High pressure valve, the parts that a high mechanical property is required, rotor bar |

(nebaru brass) | It increases by tin, but on the other hand the hardness, the strength decrease the growth. In addition, I am superior in corrosion resistance for the seawater. | Parts for the ship |

(high power brass) | The feature is that-related gadeki, corrosion resistance to pitch a camp by some manganese and aluminum being included are strong. | Forging, ship between the heat, parts for the mine |

C3604 kadomiresu RoHS correspondence (two kinds of excellent cut brass) | C3604CdL (kadomiresu) is the product which regulated cadmium by RoHS order. The kadomiresu content guarantees 75 ppm or less with standard materials in the company, and, as for the characteristic of materials, as for the conventional brass stick and difference, there are none. |

※All the Japanese Industrial Standards "JISH3250"

Original development alloy

Alloy number

| Characteristic

|

KS-B (heteromorphic brass)

| I am used for a general shape and straight angle mainly.

|

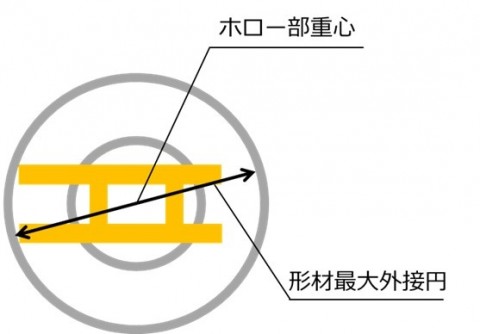

KS-H (hollow brass)

| I am used for a complicated shape with the materials which I developed for emptinesses.

|

KS-R (heteromorphic brass for building materials)

| I make the extruded nature better and am suitable for a sharp, complicated shape.

|

※Standard in the company all

Chemical ingredient

Alloy number | Cu | Pb | Al | Mn | Ni | Fe | Sn | As | Zn |

C2700

(65:35 brass) | 63.0 ...

67.0 | 0.05

The following | 0.02 The following | 0.02 The following | 0.02 The following | 0.05

The following | ― | ― | Residue |

C2800

(brass for the bending) | 59.0 ...

63.0 | 0.10

The following | 0.03 The following | 0.03 The following | 0.05 The following | 0.07

The following | ― | ― | Residue |

C3602

(one kind of excellent cut brass) | 59.0 ...

63.0 | 1.8 ...

3.7 | ― | ― | 0.20 The following | 0.50

The following | Fe+Sn 0.80% The following | 0.02 The following | Residue |

C3604

(two kinds of excellent cut brass) | 57.0 ...

61.0 | 1.8 ...

3.7 | ― | ― | 0.20 The following | 0.50 The following | Fe+Sn 0.80% The following | 0.02 The following | Residue |

C3771

(brass for forging) | 57.0 ... 61.0 | 1.0 ...

2.5 | ― | ― | 0.20 The following | Fe+Sn 1.00% or less | 0.02 The following | Residue | |

C4641

(nebaru brass) | 59.0 ...

62.0 | 0.50

The following | ― | ― | ― | 0.20

The following | 0.50 ...

1.0 | ― | Residue |

C6782

(high power brass) | 56.0 ...

60.5 | 0.50

The following | 0.20 ...

2.0 | 0.50 ...

2.5 | ― | 0.10 ...

1.0 | ― | ― | Residue |

KS-B

(heteromorphic brass stick) | 57.0 ...

61.0 | 1.8 ...

3.7 | 2.0 or less | ― | ― | 0.50

The following | Fe+Sn

1.2 or less | ― | Residue |

KS-H

(hollow brass) | 56.0 ...

60.0 | 2.5 or less | 2.0 or less | ― | ― | Fe+Sn

1.2 or less | ― | Residue | |

KS-R

(heteromorphic brass for the building) | 54.0 ...

60.0 | 3.0 or less | 2.5 or less | Mn+Ni+Fe+Sn

2.5 or less | ― | Residue | |||

(percent by weight)

※All the Japanese Industrial Standards "JISH3250"

Chemical ingredient of the cadmium 75 ppm or less brass stick

Alloy number | Name | Chemical ingredient (%) | ||||||

Cu | Pb | Fe | Sn | Al | Zn | Cd | ||

C3604 (CdL) | C3604 | 57.0 ...

61.0 | 1.8-3.7 | 0.50 or less | Fe+Sn 0.80% The following | ― | Residue | 75 ppm

The following |

C3771 (CdL) | C3771 | 57.0 ...

61.0 | 1.0-2.5 | Fe+Sn 1.00% or less | ― | Residue | 75 ppm

The following | |

KS-BC | KS-B | 57.0 ...

61.0 | 1.8-3.7 | 0.50 or less | Fe+Sn

1.2 or less | 2.0 or less | Residue | 75 ppm

The following

|

KS-HC | KS-H | 56.0 ...

60.0 | 2.5 or less | Fe+Sn

1.2 or less | 2.0 or less | Residue | 75 ppm

The following

| |

KS-RC | KS-R | 54.0 ...

60.0 | 3.0 or less | Mn+Ni+Fe+Sn

2.5 or less | 2.5 or less | Residue | 75 ppm

The following

| |

(percent by weight)

※It can be manufactured by cadmium 75 ppm or less in C2700, C2800, C3602, C4641, C6782.

※Our JIS approval product is C3604 square and a rectangle.

Chemical ingredient of the leadless kadomiresu excellent cut brass stick

Sign in the company

(alloy number) | Chemical ingredient (%) | ||||||||

Cu | Bi | Si | Sn | P | Pb | Zn | Fe | Cd | |

KS-E

(C6802) | 57.0 ... 64.0 | 0.50 ... 4.00 | ― | 0.10 ... 3.00 | 0.20 or less | 0.09 or less | Residue | 0.70 or less | 75 ppm The following |

Characteristic (reference level)

Alloy number

| Quality

| Tensile strength

N/mm²

| Growth

%

| Hardness

HV(5)

| Cutting characteristics

| The conductivity

IACS %

| Machine workability

| Bending characteristics

| The extruded nature

|

C2700

(65:35 brass)

| Heat interval

Cold

| 348

375

| 58

47

| 88

105

| 30

| 25.6

| 30

| ◎

| 80

|

C2800

(brass for the bending) | Heat interval

Cold

| 441

459

| 47

39

| 134

145

| 43

| 28.1

| 95

70

| ◎

○

| 90

|

C3602

(one kind of excellent cut brass)

| Heat interval

Cold

| 401

408

| 42

37

| 131

141

| 70

| 23.9

| 95

100

| △

X

| 100

|

C3604

(two kinds of excellent cut brass)

| Heat interval

Cold

| 408

432

| 37

33

| 128

131

| 94

87

| 22.6

| 95

100

| △

X

| 100

|

C3771

(brass for forging)

| Heat interval

Cold

| 425

445

| 40

37

| 142

148

| 65

| 25.2

| 80

90

| △

X

| 110

|

C4641

(nebaru brass)

| Heat interval

Cold

| 447

482

| 43

34

| 124

155

| 36

| 25.3

| 50

| ○

| 90

|

C6782

(high power brass)

| Heat interval

Cold

| 581

599

| 29

28

| 165

187

| 30

| 15.8

| 70

| X

| 110

|

KS-B

(heteromorphic brass stick)

| Heat interval

| 487

| 33

| 118

| 92

| 24.4

| 80

| X

| 110

|

KS-H

(hollow brass)

| Heat interval

| 566

| 28

| 129

| 60

| 26.7

| 70

| X

| 80

|

KS-R

(heteromorphic brass for the building)

| Heat interval

| 545

| 29

| 131

| 60

| 22.8

| 70

| X

| 120

|

A note: ◎The X that is ○ suitable △ possibility suitable most is impossible

Manufacturing characteristics (I suppose it to be excellent cut brass = 100) The extruded nature (I suppose it to be excellent cut brass = 100)

Production is

Solid

Jolo

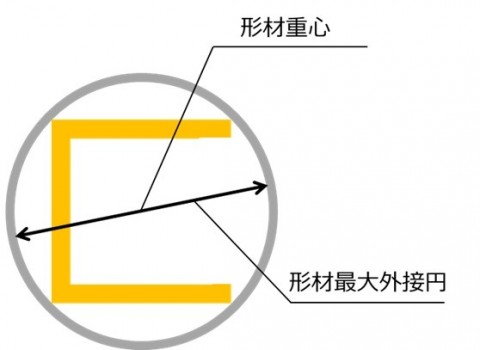

Diameter of production range by the cross-section's greatest circumscribed circle

Alloy name

| As pushing out

| Drawing

| ||

Straight angle

| Variant

| Straight angle

| Variant

| |

C3604 (two kinds of excellent cut brass)

| 70

| 70

| 60

| 60

|

C3771 (brass for forging)

C6782 (high power brass)

| 75

| 75

| 60

| 60

|

KS-B (heteromorphic brass)

KS-R (heteromorphic brass for the building)

| 75

| 75

| ―

| ―

|

C3602 (one kind of excellent cut brass)

C2800 (brass for the bending)

C4641 (nebaru brass)

| 70

| 70

| 60

| 60

|

C2700 (65:35 brass)

| 70

| 70

| 60

| 60

|

KS-H (hollow brass)

| 60

| 60

| ―

| ―

|

KS-E (heteromorphic brass)

| 70

| 70

| 60

| 60

|

(unit mm)

Production range minimum section and wall thickness by the cross-section

Alloy name | As pushing out | Drawing | ||||||

Straight angle | Variant | Straight angle | Variant | |||||

Area

㎜² | Thickness

㎜ | Area

㎜² | Thickness

㎜ | Area

㎜²

| Thickness

㎜

| Area

㎜²

| Thickness

㎜

| |

C3604 (two kinds of excellent cut brass) | 24 | 3 | 24 | 3 | 27 | 3 | 27 | 3 |

C3771 (brass for forging) C6782 (high power brass) | 24 | 3 | 24 | 3 | 27 | 3 | 27 | 3 |

C3602 (one kind of excellent cut brass)

C2800 (brass for the bending)

C4641 (nebaru brass) | 24 | 3 | 24 | 3 | 27 | 3 | 27 | 3 |

C2700 (65:35 brass) | 40 | 4 | 40 | 4 | 48 | 4 | 48 | 4 |

KS-B (heteromorphic brass)

KS-R (heteromorphic brass for the building)

| 24 | 3 | 24 | 3 | ― | ― | ― | ― |

KS-H (hollow brass) | ― | ― | 80 | 1.5 | ― | ― | ― | ― |

KS-E (heteromorphic brass) | 24 | 3 | 24 | 3 | 27 | 3 | 27 | 3 |

(unit mm)