Extruded technique

With pushing out

Characteristic of extruded materials

I can lower production cost by producing long processing not to be possible by one pushing out by the manufacturing. In addition, it produces hollow materials and complicated cross-sections as a characteristic and can make the product of the severe shape of the dimensions precision.

In addition, it is the characteristic of the pushing out product that die charges are cheaper than the die of casts such as the resin, and can cope by small lot.

In addition, it is the characteristic of the pushing out product that die charges are cheaper than the die of casts such as the resin, and can cope by small lot.

With the extrusion

We are copper elongation and extruded manufacturers of the aluminum, do you know what kind of thing this "pushing out" is?

When explain structure of pushing out; of "the tokoroten" explain that is, but, in the recent one, "tokoroten" is not explained without it being revealed. I have you image clay and talk for an image to push it to a star and the triangular model recently.

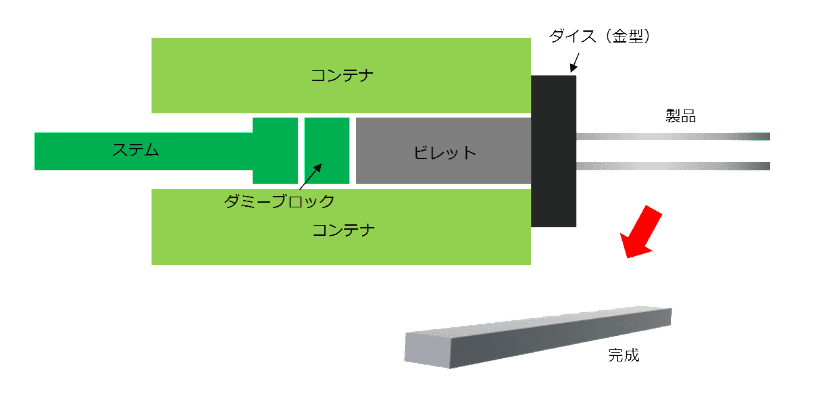

I heat the lump of the column called the billet of an alloy and the aluminum alloy of the brass, and the extrusion is a processing method between the heat to push you out of imposition, the dice hole on the dice (die) of various shapes by high pressure using an extruder, and to create slim products.

I can create even the thing of an emptiness and the complicated cross-section, the things of the shape that the dimensions precision is severe again in succession.

Because I can mold it by one process unlike other processing methods, the reduction of parts score and the assembling man-hour is enabled. I play an active part in the freedom from a merit that a rational section design is possible in a large field.

For aluminum pushing out, there are two extruded methods to be said to be direct pushing out and indirect pushing out, but takes the pushing out method by the Kaimei copper elongation directly.

Extruder

The power source of the extruder has two methods using either oil pressure or water pressure. There are many laterally-facing wide models to make pushing out horizontally, and a container and a stem are used.

I adopt a horizontal oil pressure pushing out method with the aluminum extruder of the Kaimei copper elongation and hold two engines of 7 inches of press 1800US ton and 7 inches of press 1650US ton.

Billet

A billet is the lump which was of the column cast for copper elongation and extrusion of the aluminum.

I am pushed at a high temperature and can change a form to various-shaped stick pipe-formed things.

Extrusion dies

Extrusion dies are dies to use to make materials any cross-section at the time of extrusion.

I have an influence on a cross-section, the dimensions of the product, the surface-related state, quality most.

For extruded productivity, the extruded workability, it is a very important tool.

They make use of original know-how in the Kaimei copper elongation, and all the design and development of the dice is consistent in-house.

The inquiry is this

TEL.

+81-771-23-6111

Head office time in from 8:15 to 17:30

I look forward to the inquiry over the telephone